Harvesting Machinery Process classification

The development of sugar cane harvester in China

Although many models have been developed in China, the mature and stable models that are suitable for the production of practical applications have not yet existed, and the existing models have the following problems.

To cut off type sugarcane combine harvester, because after a cut sugarcane, must be open to squeeze in 16 hours, or sugar to drop, affect the rate of sugar, and the sugar mill production mode cannot ensure timely open press, cut cut sections of combine harvester harvest sugarcane do not conform to the requirements of the sugar mill; Due to the use of wheeled tractor for chassis, the tractor should be changed greatly. Due to the large size of the machine, the turning radius is also large, and the reserve space in the sugarcane area cannot meet the requirements of the operation. The adjustable difference of the cutting table can cause the stubble to be stubble and the head rate is high. It is difficult to adjust the cutting device, and it is difficult to control the reasonable cutting length of sugarcane. The reliability of all parts of the whole machine has yet to be improved.

In our country, the whole pole type cane harvester, the rigid frame design is not enough, can not adapt to the high intensity of work; A cut sugarcane stem cut off many torn bifurcate phenomenon, resulting in the loss of sugar, sugar yield, so the cutter disc type, blade parameters such as structure, rotation speed should be modified further argument; The function is single, only the cane head is cut off, no matching peeling, cutting device. Machine overall performance is not ideal for lodging or bending righting harvesting effect is poor, to harvest more difficult line, increase the operator labor intensity, reduce the working efficiency, the overall performance remains to be improving.

Sugarcane harvesting machinery in our country and abroad developed countries gap is very big, mainly reflects in: adaptability, because of the sugar cane planting area is given priority to with hilly region, complex terrain, is a small piece of sugarcane field, our country to develop sugarcane harvester cannot very good to adapt to the actual situation, not sugar cane as developed countries shall grow large, flat area, suitable for large-scale mechanization; Due to the high price of sugarcane harvester, the policy and financial support are not very strong, the purchasing power of sugar cane farmers is limited, and the application promotion is limited. In terms of technical content, the sugarcane harvesting machinery developed in China has low working efficiency, high heteroefficiency, large loss, inadequate function and high degree of automation.

4. Countermeasures for development of sugar cane harvester in China

Cut type sugarcane harvester for serious lodging sugarcane harvest effect is better than the whole bar type harvester, the climate is warm, do not need to sugarcane leaves for thermal insulation, water, fertilizer, plot is bigger, lodging sugarcane seriously very applicable. With the development of China's economic system, it is possible to cut the sugarcane for 16 hours. Therefore, the cutting - section sugar cane harvester is worth promoting in these areas.

The whole bar type sugarcane harvester not reap serious lodging sugarcane flawed, but in the sugar cane lodging is not serious, the climate is dry, need sugarcane leaves for heat preservation, water, fertilizer, plot is larger, and cane sugar mill need longer region has the superiority. In addition, the work efficiency of the whole bar cane harvester is high, so it should be further perfected in the technology.

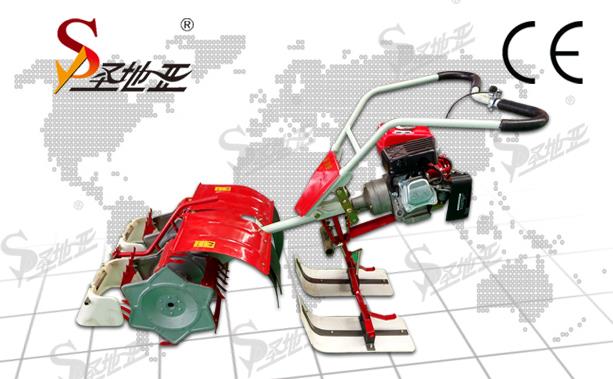

For the cane farmers of our country, small and portable harvest machinery is the most practical. For the time being, specialized small machines sorted by process are most popular. So, in the development of large sugar cane harvest machinery at the same time, should focus on the study of small sugar cane harvesting machinery system, this system can be made by some simple harvester, small-sized self-propelled sugarcane peeling machine and some auxiliary loading device. Farmers can choose different machines according to their own needs. For sugar cane harvest technology research cannot be limited to the single development and should be considered for planting sugarcane harvest machine system, transportation, such as cutting post-processing to harvest the rationality of the whole process of development suited to China's national conditions of sugarcane harvest field loading and transportation of the machinery.