power tiller To focus on repair

As the micro-farming machine working environment is relatively poor, maintenance is particularly important. In the work, due to the friction between parts and components, oil, mud, water invasion, inevitably cause the wear and tear of the parts; connection loosening, corrosion aging. So that the state of micro-farming machine deterioration, power down, fuel consumption increased, accelerated wear and tear, failures continue to emerge. In order to prevent the occurrence of the above situation, we must strictly implement the "anti-rule, pay attention to repair" maintenance system. Some players see the air cooler high temperature, worry about damage to the machine, with watering methods to help cool down. In fact, it is a very wrong practice, a sudden cooling water, the cylinder suddenly shrink, easy to pull the cylinder, broken ring, and even cylinder rupture. Fuel quality is poor, not only the machine power is not enough, but also accelerated the oil pump and core sleeve wear; micro-farming machine is equipped with aluminum alloy engine, aluminum alloy hardness is clearly less than ductile iron, so all on the body Screws must be in accordance with the provisions of the torque force, especially the cylinder head screws, a little attention will be "drawing." And try not to tighten the screws in the heat machine.

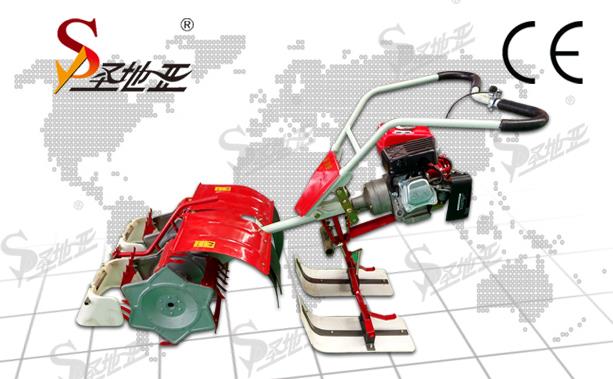

Full-wheel-wide gear micro-tillage machine was introduced to China in 1997, in Guangxi, Chongqing and other places to improve the trial production to adapt to China's more complex environment. Italy prototype machine with aluminum casting transmission box, together with the Italian local high-powered single-cylinder diesel engine, stable and reliable quality, to meet the needs of the majority of users in Europe and the United States agricultural farming. After the introduction of China, the relevant manufacturers of the aircraft for a large-scale improvement, especially since the domestic cast aluminum technology is far behind the relevant Italian industrial level, so the walking box from the original aluminum to cast iron, increased the walking box The strength of the body in contact with the ground, but also increased the weight of the machine. In 2003, the aircraft in the joint efforts of various manufacturers, and finally completed the initial transformation of the structure, the official large quantities listed. At present, most of the micro-cultivator manufacturers use single-cylinder diesel engine 6 horsepower or 9 horsepower, armrest can be up and down around the full rotation, farming tools are gradually diversified, comprehensive, able to meet the requirements of various farming around. The micro-tillage machine is designed according to the hills of our country, the small land area in the mountain area, the height difference and the large cultivated land, and specially designed for the orchard, vegetable land, greenhouse, hills and slopes. With the corresponding equipment can be pumping, power generation, spraying, spraying, harvesting, ridge, film, perforation, broken grass, rhizome harvest, soil, soil, open deep ditch, base fertilizer, Such as plains, mountains, hills, dry land, paddy fields, orchards, vegetable land, shallow rotary tillage, plowing, open furrow ridge. Micro-farming machine is a multi-functional small-scale agricultural machinery.