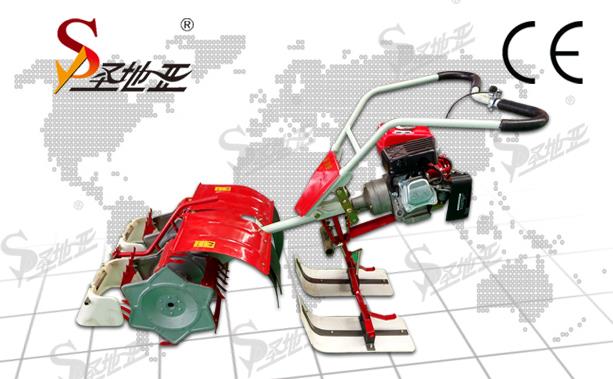

Reaper To prevent belt mechanical damage

To prevent belt mechanical damageCombine harvester is a one-time completion of picking, peeling, threshing, while the stem treatment and other operations, and then will not be bark leaves shipped to the field, after drying for threshing advanced agricultural equipment. However, the equipment no matter how good, if not often do scientific and reasonable maintenance and maintenance, there may be some failures, thus affecting the efficiency of the operation, today I here for the combine harness and chain maintenance of a comprehensive analysis, hoping to give We bring some help:

Combine harvesters V-belt maintenance points:

① in the use of the belt must always maintain the normal tension. Belt loose or too tight will shorten the service life. The belt is too loose will produce slippage, so that the work of the organization to lose performance; belt tight will make the combine harvester bearing excessive wear and tear, increase power consumption, or even pull the shaft.

② must prevent the belt into the oil.

③ must prevent the belt mechanical damage. When lifting or removing the belt, the tension pulley must be released. If the new belt is not working properly, remove a pulley and put the belt on it. The pulley groove of the same circuit should be on the same turning plane.

④ belt wheel rim with a gap or deformation should be promptly repaired or replaced.

⑤ the same loop with two or three belts, the length should be consistent. In the case of

Combine harvester chain drive maintenance points:

① The sprocket in the same loop should be on the same turning surface.

② chain should maintain the appropriate tightness, too tight easy to wear, too loose when the chain beating big.

③ adjust the chain tightness, the screwdriver inserted in the chain between the roller movement to the direction of movement of the chain, such as the tightness of the chain, should be the joint harvester chain through 20 ° - 30 °. It can be sex once finished picking, peeling, threshing, while stalk processing and other operations, of course, the price is much more expensive than other equipment. Combine harvesters are complex, moving parts and working environment is relatively poor, all the friction parts for timely, careful and correct lubrication and maintenance is very important, so not only can improve the reliability of the combine harvester, reduce friction and power consumption, But also can improve the service life of mechanical parts and reduce the use of cost, its lubrication and maintenance in addition to the machine in strict accordance with the instructions required by the time period, grease models, lubrication points for lubrication, but also should grasp the following:

1, oil used to clean the appliance. Before lubrication should be wiped the nozzle, oil, lubricating parts of the oil and dust.

2, often check the sleeve, bearing and other friction parts of the operating temperature, such as oil seal oil and the working temperature is too high should be immediately repaired and lubricated, can not be repaired immediately to shorten the lubrication interval. The lubrication parts, removable bearings, bushings, sliders, etc. should be combined with maintenance, cleaning with oil, after filling the oil filling. On the oil bearing, after the end of each year should be unloaded in the oil, soak in oil for 2 hours.