Reaper Use level and working status

Check the use of all the pulleys, sprockets, tension pulleys and belts, conveyor belts, chains and working conditions of the corn harvester, and can not be used for replacement. Chain to oil, lubricated and then equipped. After the harvester, the belt and the conveyor belt are washed with oil and coated with talcum powder, or placed in the vehicle. Playing butter and lubricating bearings and sports parts of the work and lubrication conditions, conduct a thorough and thorough inspection, bad parts to be re-adjusted or replaced, and according to the instructions required to add enough oil.

Both hands were pinch the inner and outer rings, so that in the radial and axial to do relative movement, there should be no sense of gap, a larger bearing can feel the gap, but no metal impact sound. After the completion of the above inspection and decided to purchase, the hardness test with spring spring seal spring should be no corrosion, no deformation, spring tight in the lip without loosening, if the oil seal is not correct shape, defects, elasticity, lip thickness is not Are, spring corrosion and other phenomena, indicating the quality of substandard.

Corn harvester pump can be used to tear the diaphragm layer by layer method; or the oil cloth, plastic film cut into pieces, caught in the diaphragm used. If the oil pump inside the rocker, outer rocker clearance is too large, can be metal, wire or cotter plug in the gap, and with fine wire tied firmly. With the self-propelled corn harvester in the corn growth state picking (called the station stalk picking), in the picking roller and picking plate under the action of the ear handle was pulled off. As a result of the difference between the height of the inside and outside the roller, the ear falls into the ear box, the ear is filled and the box is opened. High-speed rotation of the cutter from the root of the straw after cutting into the crushing mechanism chopped into 3-5CM long pieces, chopped straw after the natural landing.

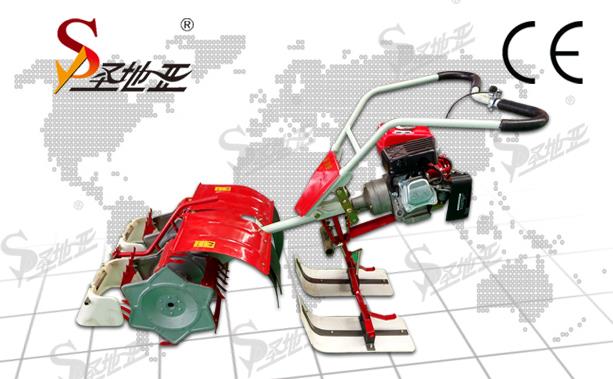

After a long period of research and production, the supply of corn harvesters can be a one-time completion of the corn crop picking, stripping, transportation, packing, straw and other production process operations, high efficiency; the second is to achieve their own It has good adaptability to different row spacing and different varieties of corn. For the production of corn harvester, adopt a new type of Wo Wo structure, and the advanced picking mechanism is quick and laborily. With the development of the times, the mechanical performance of small corn harvesters is stable; the bracelet chain plus vertical rubber wings double function wiping device, intermittent gear belt belt recovery straw mechanism, double fan rowing mechanism, front and rear axle center deceleration difference End planetary deceleration system.

Developed to fill the gaps in the province of new corn combine harvester. The model has the following characteristics: both harvest corn ear at the same time can be chopped corn rod, to the purpose of straw to the field; the unit is energy-saving, only 18-20 horsepower can easily run; Light and flexible. The unit and 20 hp small tractors supporting the use of unloading unit tractors can do other operations; high efficiency, 3-5 acres per hour can be received. Also available with corn peeling machine and corn harvester supporting the use.

In addition, the purchase of corn cutter, should focus on checking the knife beam, the straightness of the arbor and a few working gaps. Will push the power to the blade center line and the edge of the blade coincidence, then moving blade and blade edge of the front gap is not greater than 0.5mm, backside clearance is not greater than 1.5mm.